CNC 3 in 1 busbar processing machineTo cut/punch(all kingds of round/square/special holes and slot type)/chamfer/horizontal bending/ vertical bending/ emboss/Press cable thread /twist/anti-press busbar bending cutting punching machine flat the copper/aluminum busbar ect.

Product Description

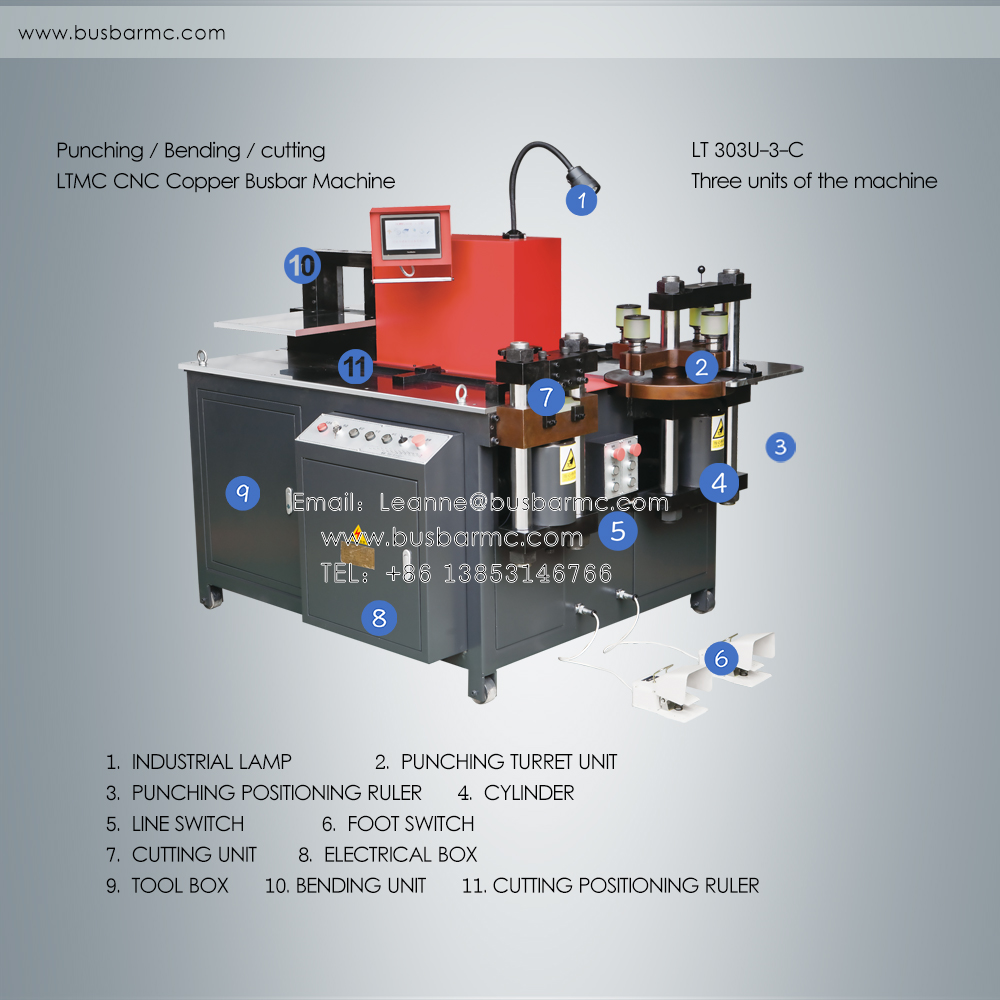

303U-3-C

This series of busbar processing machine has three processing units: punching, shearing/cutting and bending. The three unit can be used simultaneously or sequentially, the working stroke of each processing unit can be easily adjusted, which shortens the processing time and improves production efficiency. The main function is processing copper and aluminum busbar.

The busbar processing machine is equipped with three processing units: punching, shearing and bending. Through the manual button or the foot switch, the busbar can be punched, cut and bended separately, which is an ideal production equipment for the high and low voltage electrical industry.

The busbar processing machine is an auxiliary equipment designed with reference to foreign advanced products and combined with domestic actual conditions to improve work efficiency and ensure the safety of operations. It is most suitable for the construction site of large-scale electric control box and transmission and distribution construction projects.

Product Details

1. Indusutrial Lamp 2. Punching Turret Unit 3. Punching Positioning Ruler 4. Cylinder 5. Line Switch 6. Foot Switch 7. Cutting Unit 8. Electrical Box 9. Tool Box 10. Bending Unit 11. Cutting Positioning Ruler

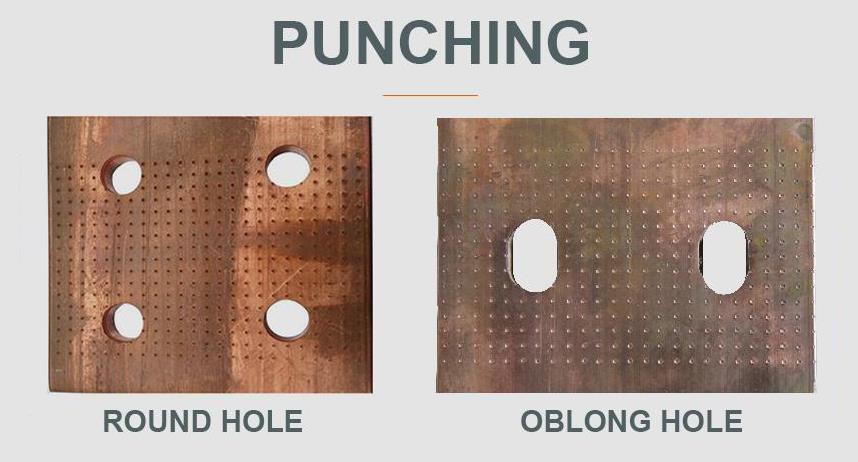

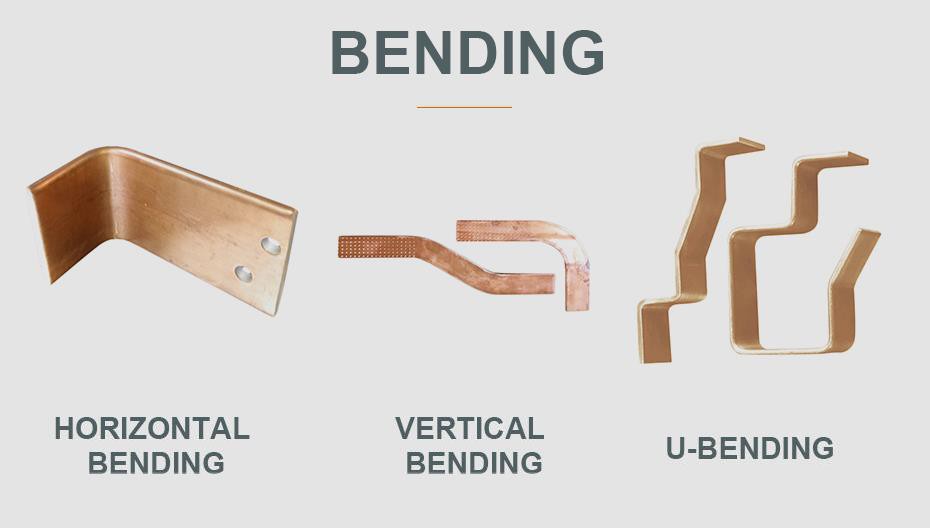

Processing Samples

You can punching round hole and oblong hole.

You can doing horizontal bending, vertical bending and U-bending.

The machine has embossing, twisting and cable connector processing functions.

Our Factory

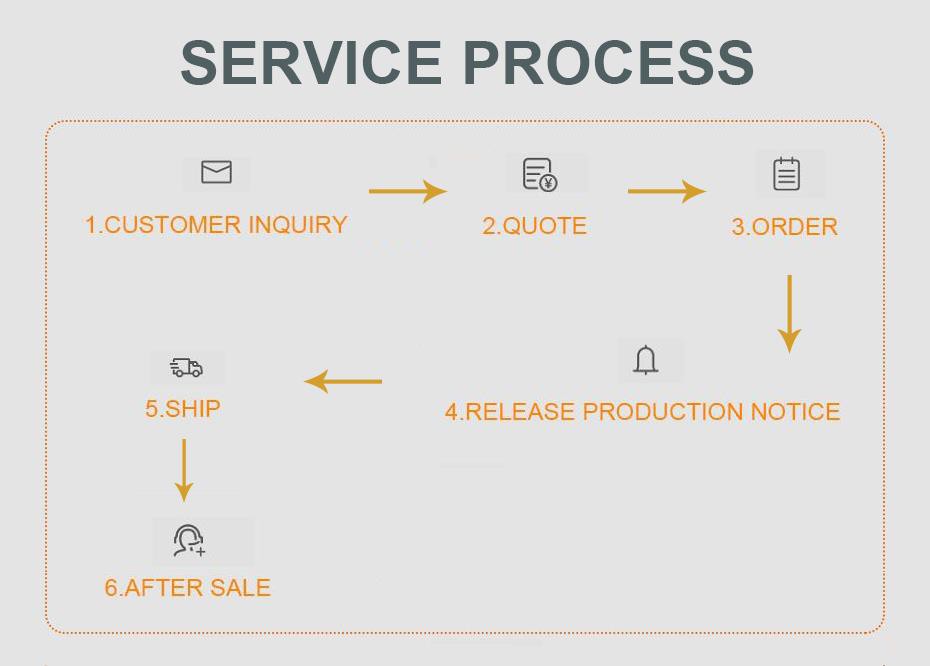

Our Service Process

Our after-sales service engineers will also have return visit to you on a regular basis to listen to your valuable opinions and continuously improve product quality.

Package & Delivery

We use waterproof plastic film wrapped inside and wooden cases outside.

Our Certifications

ISO9001 quality assurance system is the foundation of enterprise development and growth.

ISO9001 does not refer to a standard, but a general term for a standard. It is the international standard developed by TC176 (TC176 refers to the Quality Management System Technical Committee) and is the best-selling and most popular product among ISO12000 standards.

Item | Model | |

303U-3 | 303U-3-C | |

Nominal force (kn) | 300 | 300 |

Punching dia. range (mm) | ф4.3~ф25 | ф4.3~ф25 |

Max.thickness (mm) | 12 | 12 |

Max.width (mm) | 150 | 150 |

Max.shearing thickness (mm) | 12 | 12 |

Max.shearing width (mm) | 150 | 150 |

Max.horizontal bending width (mm) | 150 | 150 |

Max.horizontal bending thickness (mm) | 12 | 12 |

Max.vertical bending size (mm) | 10×100 | 10×100 |

Power (kw) | 1×4KW | 3×4KW |

Table size (mm) | 1650×1050 | 1650×1050 |

Outside dimension (mm) | 1720×1220×1220 | 1720×1220×1220 |

Container size (mm) | 1800×1300×1430 | 1800×1300×1430 |

Total weight (kg) | 1220KG | 1320KG |

Main Features

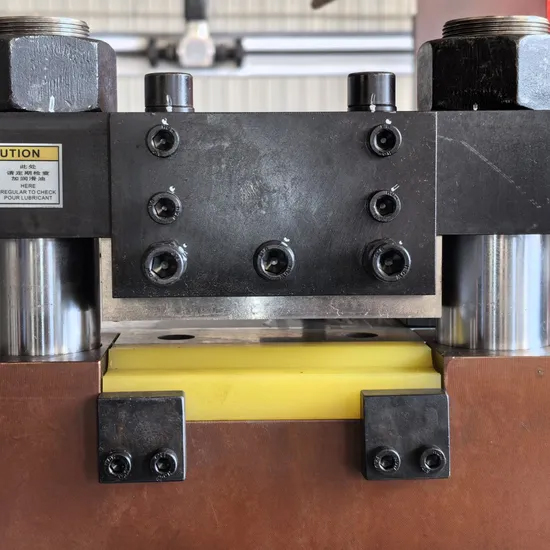

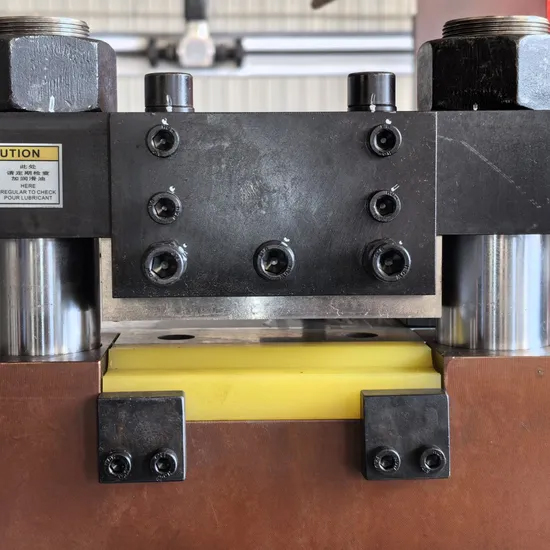

1. The cutting processing unit adopts vertical processing mode, flexible and convenient to operate. It adopts flat blade cutting, and the incision interface of workpiece is flat, no waste, burrs and droop.

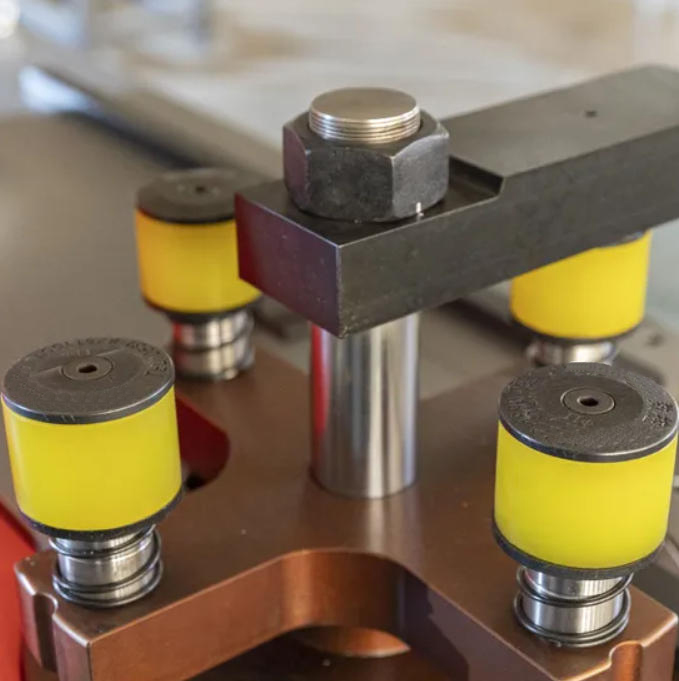

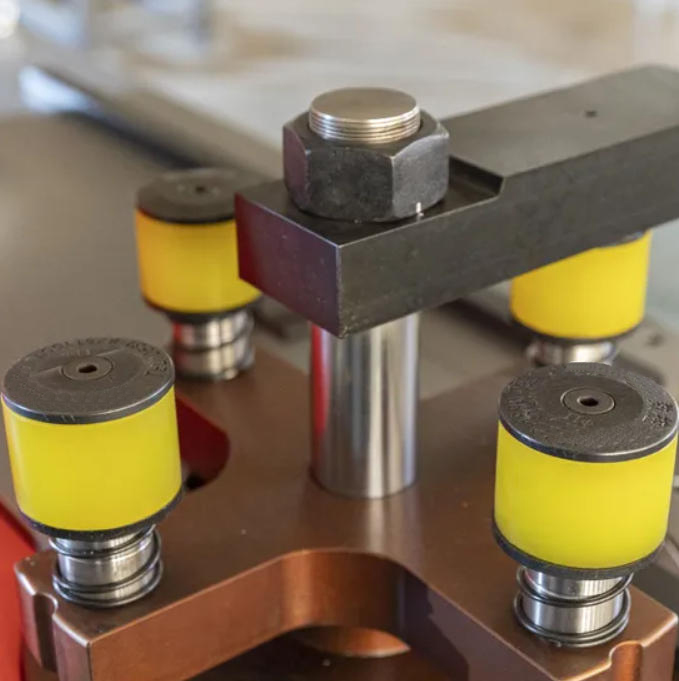

2. The punching unit uses a six-mode turnplate in tooth shape with good view, and no need to change the dies frequently, and the operation is simple and efficient.

3. The bending unit adopts a horizontal bending. By changing molds, could be completed the processing of flat bending or vertical bending.

4. A variety of processing functions such as embossing, flattening, twisting, and crimping of cable ends can be achieved by changing the molds.

5. The machine has four casters, so it is easy to be moved everywhere needed.

6. Different molds or tools can be installed according to user requirements to complete special shape processing.

Hot Tags: 303U-3-C 3 in 1 manual hydraulic busbar machine busbar processing machine, China, suppliers, manufacturers, factory, price

LT Busbar Machine Videos:

303U-3-C 3 in 1 manual hydraulic busbar machine FAQ:

1. What is the 303U-3-C 3 in 1 manual hydraulic busbar machine used for?

The 303U-3-C busbar processing machine is designed for punching, shearing/cutting, and bending copper and aluminum busbars, making it ideal for high and low voltage electrical industry applications.

2. Can the three processing units work simultaneously?

Yes, the punching, cutting, and bending units can operate simultaneously or sequentially, allowing for flexible operation and improved production efficiency.

3. How are the punching, cutting, and bending functions controlled?

The machine can be controlled via manual buttons or a foot switch, enabling the operator to perform punching, cutting, or bending separately as needed.

4. What are the main features of the 303U-3-C busbar machine?

The machine features vertical cutting with flat blade incision, a six-mode turnplate punching unit, horizontal bending with interchangeable molds, embossing, flattening, twisting, crimping functions, and four casters for easy mobility.

5. What are the machine’s specifications?

Nominal force: 300 kN; Punching diameter range: ф4.3–ф25 mm; Max thickness: 12 mm; Max width: 150 mm; Power: 3×4 kW; Table size: 1650×1050 mm; Total weight: 1320 kg.

6. Is the 303U-3-C suitable for construction sites?

Yes, it is designed for use in large-scale electric control box construction and transmission and distribution projects, ensuring efficient and safe operations.

7. How is the machine shipped and packaged?

The machine is wrapped with waterproof plastic film inside and secured in wooden cases for safe transportation.

8. What certifications does the 303U-3-C busbar machine have?

The machine adheres to ISO9001 quality management standards, ensuring reliability and consistency in performance.

9. Can the machine perform special shape processing?

Yes, different molds or tools can be installed according to user requirements to achieve custom shapes, including horizontal, vertical, and U-bending, as well as embossing, twisting, and crimping.

10. Is after-sales support available for the 303U-3-C?

Yes, after-sales service engineers provide regular follow-ups to address customer feedback and continuously improve product quality.

303U-3-C busbar machine, 3 in 1 hydraulic busbar machine, manual busbar processing machine Hot Tags:

303U-3-C busbar machine, 3 in 1 hydraulic busbar machine, manual busbar processing machine, copper busbar bending machine, aluminum busbar processing equipment, CNC busbar punch shear bend machine, high voltage busbar machine, low voltage busbar machine, portable busbar machine, industrial electrical busbar machine, customizable busbar processing machine, busbar fabrication machine, multi-function busbar machine, compact busbar machine, hydraulic busbar bending press